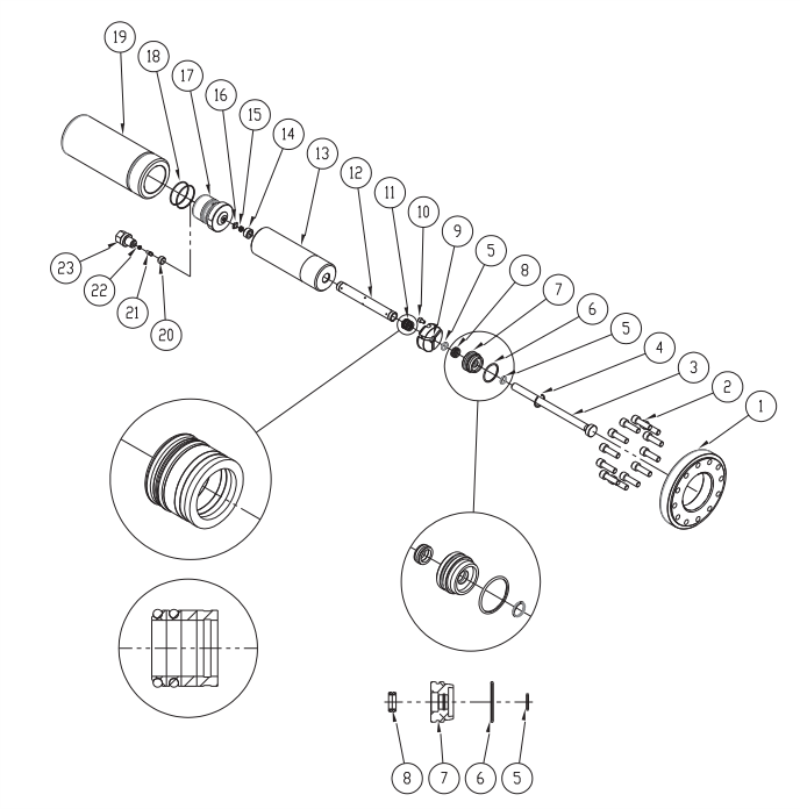

Techni Waterjet O-ring 500-5-0089

The TECHNI Waterjet O-ring 500-5-0089 is a specific component designed for sealing applications within TECHNI waterjet cutting systems. O-rings are critical for maintaining the integrity of high-pressure systems by preventing leaks and ensuring that various parts of the system are securely sealed.

Key Aspects of the TECHNI Waterjet O-ring 500-5-0089

Material: The O-ring is likely made from a robust material capable of withstanding the harsh conditions of waterjet cutting, such as:

Nitrile (Buna-N): Resistant to oils and many chemicals, suitable for lower temperatures.

Viton (FKM): Excellent chemical and heat resistance.

EPDM: Good for water and steam applications, with excellent weathering and ozone resistance.

Silicone: High-temperature tolerance and flexibility, but generally less chemical resistant.

Dimensions: The specific inner diameter (ID), outer diameter (OD), and cross-sectional thickness (CS) must match the requirements of the component or assembly it is used in.

Compatibility: Ensure the O-ring material is compatible with the fluids and operational environment of the waterjet system, including any abrasive slurries and cutting fluids used.

Functions of the O-ring

Sealing: Provides a tight seal between connected parts to prevent leaks and maintain system pressure.

Pressure Maintenance: Ensures the high-pressure integrity of the system by preventing fluid escape.

Contaminant Protection: Keeps out contaminants that could interfere with the system's performance.

Maintenance Tips for O-rings

Regular Inspection: Periodically inspect O-rings for wear, cracking, or any signs of degradation. Replace any damaged O-rings promptly.

Proper Installation: Ensure O-rings are installed correctly, without any twisting, stretching, or pinching. Use the appropriate tools and lubricants to facilitate proper installation.

Lubrication: Apply compatible lubricants during installation to prevent damage and ensure a proper seal.

Storage: Store spare O-rings in a cool, dry place, away from direct sunlight and chemicals that could cause degradation.

Troubleshooting Common Issues

Leaks: Inspect the O-ring for damage or improper installation if leaks occur. Ensure it is the correct size and material for the application.

Pressure Drops: A damaged or improperly seated O-ring can cause pressure drops. Inspect and replace the O-ring as necessary.

Degradation: Exposure to incompatible fluids or extreme temperatures can degrade the O-ring material. Ensure the material is suitable for the specific operating conditions.

If you are interesting in TECHNI Waterjet,Contact us any time.

wwaterjet

wwaterjet