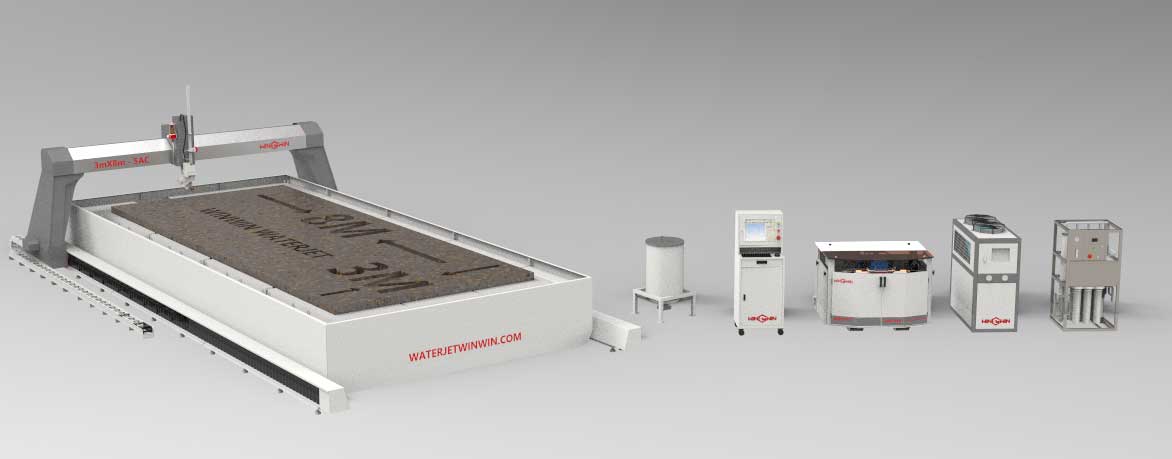

Innovation Leads the Future of Manufacturing: The Orbital 3×8-meter Waterjet Cutting Platform Officially Enters Production

(Shenyang, China) – As global manufacturing continues to demand ever-increasing precision and efficiency in machining large workpieces, the recent official launch of the Orbital 3×8-meter Waterjet Cutting Platform marks a new era in industrial cutting technology. With its ultra-large processing envelope, high-precision control system, and broad application adaptability, this platform is rapidly becoming a core piece of equipment in industries such as aerospace, shipbuilding, heavy machinery, and composite materials processing.

Technological Breakthrough: A Perfect Combination of Ultra-Large Size and High Precision

The Orbital 3×8-meter Waterjet Cutting Platform utilizes an advanced rail-type (gantry) design, ensuring exceptional rigidity and stability throughout its 8-meter processing envelope. Its core advantages include:

Extremely Large Processing Volume: With an effective cutting area of 24 square meters, it can process entire large sheets in a single pass, significantly reducing errors and time waste caused by repeated workpiece positioning.

High-Precision Control: Positioning accuracy reaches ±0.025mm, and cutting accuracy is controlled within ±0.10mm, meeting the machining requirements of high-precision components.

Multi-Axis and Five-Axis Cutting Capabilities: Supports five-axis linkage (X, Y, Z, A, and C), with a maximum bevel cutting angle of ±70°, suitable for precision machining of complex 3D surfaces.

Core Performance Parameters: Tailored for Heavy Industry

This platform excels in key performance indicators, fully meeting the stringent demands of the heavy industry:

Cutting Thickness Range: 1–150mm, covering a wide range of materials from thin sheets to ultra-thick metals and composites.

Power System: Standard 37kW high-pressure booster pump with a maximum pressure of 420 MPa ensures efficient cutting capabilities.

Control System: Based on an industrial-grade operating system, it supports G-code and various CAD/CAM file formats, enabling fully automated operation and remote real-time monitoring.

Environmental Protection and Safety: Utilizing cold cutting technology, there is no heat-affected zone, no toxic gas emissions, and complies with international CE safety certification standards.

Widely applicable, empowering multiple key industries

This equipment has demonstrated its strong adaptability in a variety of fields:

Aerospace: Suitable for cutting fuselage components and structural parts made of difficult-to-machine materials such as titanium alloys and carbon fiber composites.

Shipbuilding: Enables precision machining of ultra-thick steel plates and curved hull plates in a single pass, significantly improving shipbuilding efficiency.

Energy and Heavy Machinery: Efficient machining of wind turbine towers and large structural components for mining machinery.

High-end Decorative Materials: Custom-shaped cutting and artistic shaping of stone, glass, and composite panels.

Equal emphasis on intelligence and sustainable development

The platform integrates Internet of Things (IoT) technology, enabling real-time monitoring and data analysis of equipment operating status, enabling predictive maintenance and minimizing unplanned downtime. Furthermore, the mean time between failures (MTBF) of key components exceeds 8,000 hours. By optimizing abrasive usage and water recycling systems, operating costs and environmental impact are significantly reduced.

Market Response and Customer Collaboration

The platform has now entered mass production and has successfully received orders from international markets including Thailand. To further deepen international cooperation, Win-Win Waterjet Co., Ltd. recently extended a formal invitation to its Thailand partner,to arrange for their customer team to travel to China for a factory acceptance test (FAT) and technical exchange.

"We firmly believe that our track-mounted 3x8 meter waterjet cutting platform will provide companies with unprecedented processing flexibility and precision," said Anna, a spokesperson for Win-Win Waterjet. "We look forward to jointly promoting the transformation and upgrading of the heavy manufacturing industry through continuous technological innovation and global collaboration."

About Win-Win Waterjet Co., Ltd.

Win-Win Waterjet Co., Ltd. is a national high-tech enterprise specializing in the research, development, manufacturing, and service of high-end waterjet cutting equipment. Its products range from standard models to customized large-scale platforms, and are sold in over 30 countries and regions worldwide. With a focus on technological innovation, the company is committed to providing efficient and environmentally friendly cutting solutions to industrial customers worldwide.

wwaterjet

wwaterjet