Clamp ring SP4-50

Part Name: Clamp Ring SP4-50

Common Names in Chinese: Clamp Ring / Pressure Ring / Retaining Ring

System: Water Jet Cutting Machine High-Pressure Pump Seal Assembly

Function and Positioning

1.The Clamp Ring SP4-50 is used to securely secure components such as the seal housing, seal kit, or liner in the high-pressure cylinder. This ensures that these components do not shift under high pressure (typically 3,800–4,100 bar / 55,000–60,000 psi).

2. High-Pressure Withstanding

As a metal ring, it can withstand strong axial and radial forces, preventing components from loosening during the reciprocating motion of the intensifier.

3. Extended Lifespan

A suitable clamp ring design can reduce seal wear and increase the overall lifespan of the high-pressure pump seal assembly.

Precautions for Use

Pay attention to direction and tightening force during installation: Too loose a clamp ring can cause seal leakage, while overtightening can damage the O-ring or seal. Replacement Cycle: Typically replaced during seal assembly overhaul (approximately 600–1000 hours, depending on operating environment).

Inspect for wear: If the clamp ring is cracked, worn, or deformed, it must be replaced promptly. Failure to do so may result in seal failure or even a high-pressure accident.

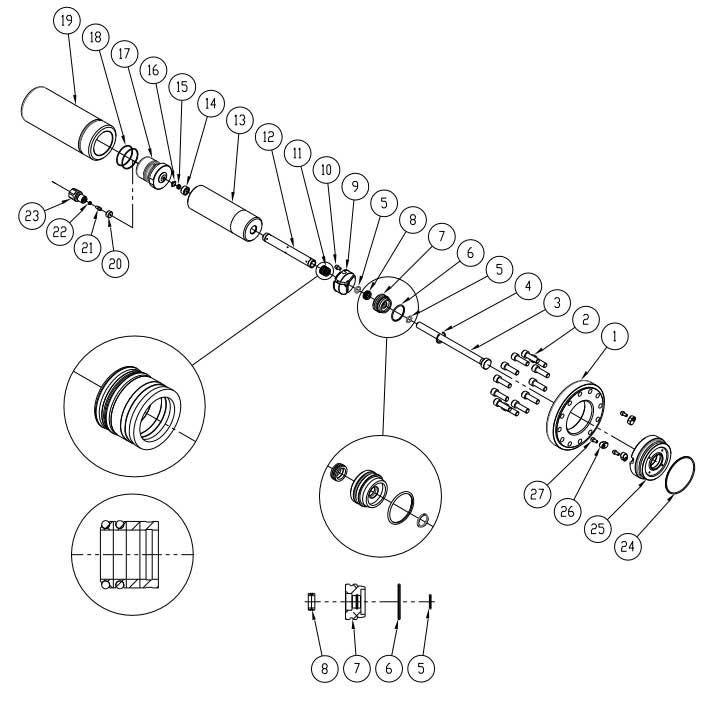

ITEM NO. | Description | Part Number | Quantity |

1 | Clamp ring | SP4-50 | 1 |

2 | M12x1.25x40 SHCS BLK | 110-1-1240 | 12 |

3 | Plunger | SP-46-3 | 1 |

4 | Internal Circlip | 501-1-0010 | 1 |

5 | O-ring | 500-5-0049 | 2 |

6 | O-ring | 500-5-0089 | 1 |

7 | Seal Housing | SP4-45-175 | 1 |

8 | Wiper Seal | SP1042 | 2 |

9 | Guide Bush | SP4-46-175 | 1 |

10 | M6 x 10 SHCS Black | 108-1-0610 | 1 |

11 | HP Seal Kit | SP1060 | 1 |

12 | Cylinder Liner | SP4-69-175 | 1 |

13 | Cylinder Body | SP-49-13 | 1 |

14 | Check Valve Housing | SP-72-7 | 1 |

15 | LP Check Valve Spring | 500-12-0040 | 1 |

16 | Check Valve Poppet | SP-73-2 | 1 |

17 | Sealing Head | SP-71-9 | 1 |

18 | O-Ring- BS033 | 500-5-0042 | 2 |

19 | Cylinder Retaining Sleeve | SP2-70-5 | 1 |

20 | Valve Seat | 500-20-0111 | 1 |

21 | Outlet Poppet | 500-20-0113 | 1 |

22 | Spring | 500-20-0112 | 1 |

23 | Check valve outer body | 500-20-0100 | 1 |

24 | O-ring | 500-5-0111 | 1 |

25 | End Cap Insert | SP4-125 | 1 |

26 | Clamp | SP4-126 | 3 |

27 | M6 x 12 SHCS Black | 108-1-0612 | 3 |

NA | Collar | 10078715 | 1 |

NA | Gland nut 3/8" | 10078129 | 1 |

High Pressure Outlet Poppet Repair Kit | 500-20-0110 | ||

20 | Valve Seat | 500-20-0111 | 1 |

21 | Outlet poppet | 500-20-0113 | 1 |

22 | Spring | 500-20-0112 | 1 |

Guide Bush Assembly Kit G4 | SP1120 | ||

5 | O-ring | 500-5-0049 | 2 |

6 | O-ring | 500-5-0089 | 1 |

7 | Seal Housing | SP4-45-175 | 1 |

8 | Wiper Seal | SP1042 | 2 |

9 | Guide Bush | SP4-46-175 | 1 |

wwaterjet

wwaterjet

-Sugino-waterjet-pump-parts.1379.1.jpg)